Direct Combustion in Biomass Power Plants

Giant King Grass is suitable as a fuel for direct combustion (burning) in 100% biomass electricity-generating power plants. Today, biomass power plants are fueled by agricultural and forestry waste such as corn stover, wheat straw, rice husks and wood waste. The price of agricultural waste has increased dramatically in China and India due to market demand, and in many areas, growing Giant King Grass as a dedicated energy crop is less expensive and more reliable than using waste. Agricultural waste is seasonal, because it is only available after the food crop such as corn is harvested. The corn stover must be gathered over long distances because the yield is quite low, then dried, baled, stored and utilized as fuel until the next agricultural waste crop is available. Reliability, consistency and cost of biomass fuel are the major issues facing biomass power plants today. A dedicated Giant King Grass plantation co-located with a power plant is a cost effective and reliable solution to producing clean electricity.

Direct Combustion-Overview

DP CleanTech 30MW Biomass Electric

Power Plant Suitable for Giant King Grass

Direct combustion (or "direct-fired") systems burn biomass in boilers to produce high pressure steam. The steam turns a turbine connected to a generator-the same kind of steam-electric generator used in fossil fuel power plants. As the turbine rotates, the generator turns, and electricity is produced. This is the simplest and oldest way to generate electricity from biomass. To increase the energy-producing efficiency of direct combustion, power plants also operate cogeneration facilities, which capture waste heat and "secondary" steam and use it to heat buildings and provide steam and heat for industrial processes such as ethanol production or drying of chemical and wood products.

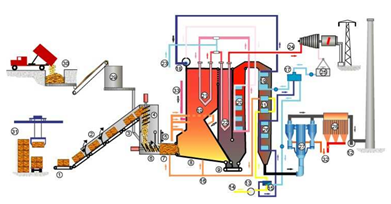

Schematic of Direct Combustion Process. Biomass is delivered and burned in the

boiler which heats water into steam that powers a steam turbine and generator.

Corn stover bales at DP CleanTech power plant.

Baling is only necessary if the fuel needs to be

transported over long distances and stored

or stored for several months. The bales are broken

up before entering the boiler.